AN OUTSIDE VIEW

POLITICS ∙ ECONOMICS ∙ RELIGION ∙ MUSIC

fredag 21 april 2023

Ultimate net zero lunacy?

fredag 21 oktober 2022

Brexits misslyckande

torsdag 16 juni 2022

Västtrafiks virtue signalling for Pride month

Regnbåge flaggar på fordon. Behövs inte. De retar upp folk i onöd, särskilda muslimer för att det går emot sina tro. Det finns tillräckliga regnbåge och flaggor och varianter i stan under Pride månad. Det skulle bli bättre att lägga er uppenbarliga bristande resurser och pengar till rengöring av GS spårvagnars smutsiga ytor med hänsyn till de ljusmålade ytor övanpå fönster. Och att fixa nummerskyltar.

Svar från Västtrafik

Tack för att du hörde av dig till oss på Västtrafik! Att ställa sig bakom budskapet om allas lika värde är en självklarhet för oss. Alla ska känna sig välkomna i kollektivtrafiken. Genom att flagga tar vi ställning för det färgerna symboliserar – inkludering och mångfald. Västtrafik står bakom West Prides vision om en jämlik och inkluderande värld fri från fördomar och diskriminering. Om du har en specifik klagomål på nogon buss som inte funkar eller är trasig kan du såklart återkomma till oss med en specifik tur det gäller på och vi kollar närmare på det. Skulle du ha någon annan fundering så är du varmt välkommen att återkomma. Jag önskar dig en fin dag!

Mitt Svar

torsdag 16 december 2021

The real epidemic

There is some bad science driving the current policies of fresh lockdowns and

vaccine passports. The initial virus was indeed dangerous because it had crossed

from wild animals to humans. This happened probably due to research which nobody

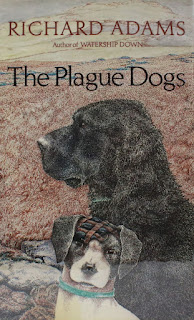

should be doing (as in The Plague Dogs published in 1977 and written by

Richard Adams, author of the better known Watership Down).

There is some bad science driving the current policies of fresh lockdowns and

vaccine passports. The initial virus was indeed dangerous because it had crossed

from wild animals to humans. This happened probably due to research which nobody

should be doing (as in The Plague Dogs published in 1977 and written by

Richard Adams, author of the better known Watership Down).My guess is that the vaccine was a wild one which had been brought in for study to the research laboratory. My further guess is that it escaped not because anyone caught it, but because the laboratory animals are routinely sold off to the local market traders instead of being incinerated, as a perk of the job for under-paid technicians. Although this seems to have been a laboratory-induced pandemic, poor agricultural and food handling practices are another important contributor to pandemics generally, including living too close to animals and crowding animals together unnaturally.

Once pathogens get into human populations, Darwinian natural selection applies. The most contagious ie the mildest version survives. It does not help the virus to spread if it kills, or sends to bed, whoever it infects. Although we will not know for another couple of weeks, the omicron mutation seems to be the end of the road for this virus. If the virus is no more dangerous than a common cold, as seems likely on the evidence so far, lockdowns, passports and booster vaccines are exactly what should not be applied; it seems as if we have a natural vaccine and it should be encouraged to spread as fast as possible.

The poor outcomes from the original version of Covid seem to have been due largely to the pre-existing epidemic of malnutrition, including overweight and vitamin deficiency. Nobody in authority seems to want to talk about these issues.

Covid is probably over but there will be other pandemics. Action needs to be taken to reduce the risk, and everyone needs to be better prepared. The root causes need to be tackled.

torsdag 19 november 2020

onsdag 14 oktober 2020

Mutually self-punishing trade policy

The government of country X subsidises widget production by giving its taxpayers' money to Widgeprod Inc. Its taxpayers are the losers.

Widgeprod then sells its subsidised widgets in country Y, which makes them good value to those who can buy them. Widgeproduits SA is threatened with the loss of most of its business and persuades the its own government to put a tariff on everything from country X.

This keeps Widgeproduits AS in business but everyone else in country Y paying through the nose for all imports from country Y.

The alternatives would have been for Widgproduits AS to side-step the competition by making something else (these situations rarely develop overnight) or cease production. The money customers save on the cheaper Widgeprod goods is spent elsewhere into the economy of country Y, and the foreign exchange that flows into country X is ultimately spent in country Y.

The subsidy is a net economic loss to country X. The punitive tariffs are a loss to country Y. Why does this idea of mutual self-harm persist?fredag 9 oktober 2020

What is Land Value Tax? Part 3

Ultimate net zero lunacy?

The ultimate net zero lunacy is probably de-carbonising and trying to electrify the entire railway system. In the first place, the railways...

-

I wrote to my MP on two entirely separate issues recently. The first was to do with the replacement for the Inter City 125 train, which at £...

-

The ultimate net zero lunacy is probably de-carbonising and trying to electrify the entire railway system. In the first place, the railways...

-

The FT has run a couple of pieces on Sweden this week. The first was a report of the outbreak of car burning, the second, today, on the rise...